What Is Backfilling in Mining?

Backfilling is a crucial process in mining that involves refilling excavated areas with materials to maintain structural stability and reduce environmental impact. This practice is widely used in both construction and the mining industry, especially in underground operations.

One of the main purposes of backfilling in underground mines is to provide support to the surrounding rock mass, which helps prevent cave-ins and surface subsidence. It also plays a key role in minimizing ore dilution, ensuring safer working conditions for miners, and reducing the amount of waste that needs to be stored on the surface.

Additionally, backfilling can serve as an environmentally friendly way to manage mine waste. By using tailings and other byproducts as backfill material, mining companies can reduce their ecological footprint and avoid potential contamination of nearby water sources.

[Note: The term "backfilling" is sometimes written as "back filling," but the single-word version is more commonly used in technical contexts.]

Types of Backfill

Backfill materials are typically composed of waste products from the mining process, such as tailings, which are the leftover materials after the valuable minerals have been extracted. These materials are often processed and mixed with binding agents to create a stable and durable backfill.

Backfilling in underground mines—a truck hauling ore

Backfilling in underground mines—a truck hauling ore

The following are some common types of backfill used in mining:

- Cemented backfilling: This method involves mixing tailings with cement to create a solid, cohesive material that fills voids. It's ideal when only small amounts of cement are needed due to its high cost.

- Dry rock backfilling: This uses dry materials like gravel, sand, or crushed rock to fill mined-out areas. It's often used in cut-and-fill mining methods.

- Hydraulic sand backfilling: Fine sand is separated from tailings and pumped into voids under pressure. It can be mixed with binders if necessary.

- Paste backfilling: A thick, slurry-like mixture of tailings, water, and binders is used, particularly in coal mining. It provides strong structural support and is easy to pump over long distances.

The Mine Backfilling Process

The backfilling process varies depending on the type of mine, the nature of the tailings, and the location of the stope (the area being mined). In most cases, heavy machinery is used to pump the backfill material into the voids. For shallow mines, gravity and dump trucks may be sufficient for the task.

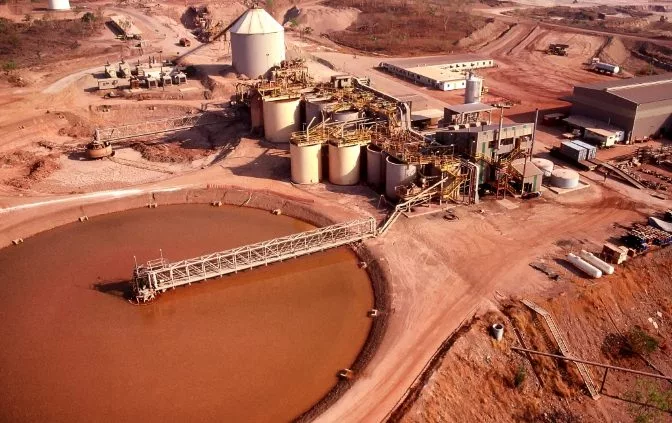

Tailings plant

Tailings plant

Many underground mines use cemented paste backfill, which is produced at the surface in large processing plants. Tailings are first dewatered using filters, then mixed with binders and transported via high-pressure pumps to the mine site. Bulkheads or barricades are placed at the entrance of the stope to hold the backfill in place while it cures.

Mine Backfilling Process Hazards

While backfilling is essential, it also comes with several risks. Some of the most common hazards include:

- Backfill segregation: Particles can separate during curing, leading to uneven distribution and potential instability.

- Backfill sloughing: The top layer of cured backfill may break away, causing fresh backfill to shift.

- Borehole clogging: Materials can get stuck in boreholes, requiring additional drilling to access the mine.

- Bulkhead failure: If the barrier holding the backfill fails, it can lead to serious safety issues.

- Pipe hammering: Sudden pump shutdowns can cause damage to pipelines.

- Pipeline burst: Overpressure or blockages can result in ruptured pipes.

- Plugged pumps: Pumps may become clogged or wear out over time.

- Plugged sump: A blocked sump can affect ventilation and require cleanup.

- Pump failure: Blockages or mechanical issues can disrupt the flow of backfill.

Advantages and Disadvantages of Backfill Mining

Backfill mining offers numerous benefits, making it a popular choice in many mining operations. However, it also has some drawbacks that should be considered before implementation.

Advantages of Backfill Mining

- Improves mine stability and safety.

- Enables recovery of residual minerals in pillars.

- Reduces the risk of rock bursts and collapses.

- Helps control groundwater contamination.

- Enhances ventilation in underground spaces.

- Minimizes acid rock drainage (ARD).

- Prevents roof falls during blasting.

- Reduces the need for surface waste storage.

- Lessens environmental impact upon mine closure.

- Helps prevent mine collapse in room and pillar systems.

Disadvantages of Backfill Mining

- Requires expensive pumping equipment and infrastructure.

- Demands a dedicated tailings processing plant.

- Needs additional labor and equipment management.

- Can be costly when binders are involved.

- May slow down the overall mining rate.

- Increases risk of liquefaction during seismic events.

- Could lead to groundwater contamination if not properly managed.

- Requires significant energy and resources for dewatering and transport.

Taixing Yingxing Composite Material Co.,Ltd , https://www.ptfecnyx.com