Texo Case Study: Inspection of Oil Tanks on an FPSO

TEXO leverages Elios drones to enhance safety, efficiency, and data accuracy during oil tank inspections on FPSOs. Discover how this technology is transforming the industry.

Key Benefits at a Glance

|

Savings

Traditional inspections require 4–5 rope access technicians, who must wait until tanks are emptied and cleaned. This process can take 7–10 days per tank, leading to high labor costs and production downtime. With Elios 3, only two people are needed for 2 days per tank, significantly reducing both costs and operational disruption. |

Speed

Traditional methods can take up to 10 days per tank, while Elios 3 cuts this down to just 2 days. The ability to prioritize high-risk areas allows for faster identification of issues and more efficient maintenance planning. |

|

Safety

Inspecting oil tanks traditionally involves working at height for extended periods, posing significant risks. Elios 3 allows pilots to remain safely outside the tank, eliminating exposure to confined spaces and hazardous environments. |

Operational Efficiency

Drones reduce the number of personnel required, which helps in managing crew space on FPSOs—where space is often limited. This also allows operators to allocate resources more effectively for other critical tasks. |

Introduction

Floating Production, Storage, and Offloading (FPSO) vessels play a crucial role in offshore oil operations. These large ships are designed to process, store, and offload crude oil, offering flexibility and efficiency in remote locations. They can be relocated as needed, making them ideal for long-term production strategies.

Typically, FPSOs have processing equipment above deck and storage tanks below. These vessels operate with a crew of 50–70 people and must undergo regular inspections for safety and regulatory compliance. However, inspecting internal structures like oil tanks is a complex and risky task.

Customer Needs

TEXO was tasked with inspecting oil tanks on an FPSO. While dry dock inspections can be done with scaffolding and teams, in-station inspections are far more challenging. Tanks cannot be emptied simultaneously due to balance and operational constraints, limiting the number that can be inspected at once.

The traditional method requires 4–5 rope access technicians, who may wait weeks for tank preparation. Once available, the inspection is time-consuming and dangerous, often requiring scaffolding, which introduces additional risks. The downtime caused by these inspections is costly, not just in labor but in lost production time.

Solution

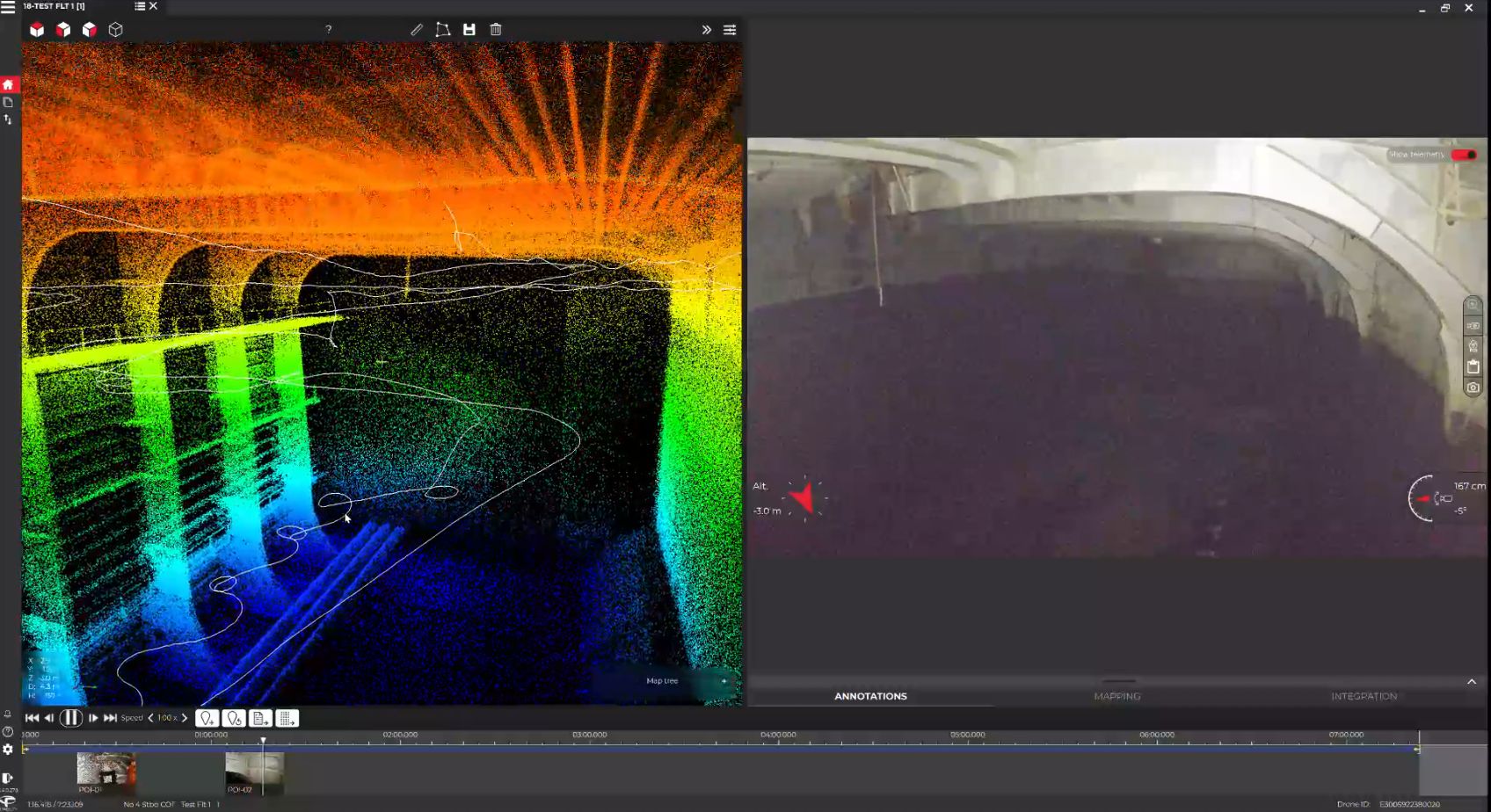

TEXO used the Elios 3 drone to complete the inspection in one week with just two personnel. The pilot remained safely outside the tank, ensuring no risk to the team. Four flights were conducted to map the tank, generating a detailed 3D point cloud for analysis.

According to TEXO’s Xiang Wong, “Elios is such a game-changer. It reduces the number of people needed and ensures full coverage of the tank.†He added, “With Elios 3, we can track our flight path and ensure nothing is missed. This gives onshore engineers confidence that every part of the tank has been thoroughly checked.â€

Compared to rope access, where inspectors rely solely on their judgment and images, Elios provides continuous video and location data, allowing multiple experts to review the same dataset and add their insights over time.

One key example was the steam heating coils located inside the tank. These are fragile and hard to inspect manually. Using Elios 3, TEXO could navigate around them safely and generate a point cloud, enabling engineers to pinpoint issues accurately and plan repairs efficiently.

Results

TEXO completed the inspection in just 4 days instead of the usual 2 weeks. The client received high-quality point cloud data that was previously unattainable, and the results were well-received. The client is now considering using Elios for future inspections on FPSOs.

The use of Elios ensured zero risk to personnel and provided onshore engineers with full confidence in the completeness of the inspection. This level of detail and accuracy is essential for maintaining the integrity of critical infrastructure.

Conclusion

TEXO has seen substantial value in using Elios drones, particularly the Elios 3, for various oil and gas inspection projects. While Elios 2 offers many benefits, the addition of location referencing and point cloud data in Elios 3 makes it ideal for problem-solving and repair planning.

Xiang Wong notes, “If everything is fine, Elios 2 is sufficient. But for identifying and addressing issues, Elios 3 is a must.†Looking ahead, TEXO plans to explore new applications, such as inspections on semi-submersible vessels, which are complex and difficult to navigate.

“The Elios 3 is perfect for those environments,†he says. “It eliminates the need to send people into confined spaces, making inspections safer and more efficient.â€

TEXO Group is certified by DNV as an approved service provider for using UAVs in remote inspections of ships and mobile offshore units.

Product Brochure,Video Brochure,Furniture Brochure,Construction Brochure

Jiangmen Yingzhihui Electronic Commerce Co., LTD , https://www.yzhprint.com