Discover the World of Custom Sheet Metal Boxes

- Why custom sheet metal boxes are essential in modern industries.

- Key benefits, design process, material choices, and fabrication techniques for custom sheet metal boxes.

- How to select a reliable manufacturer and maintain your sheet metal boxes for long-term use.

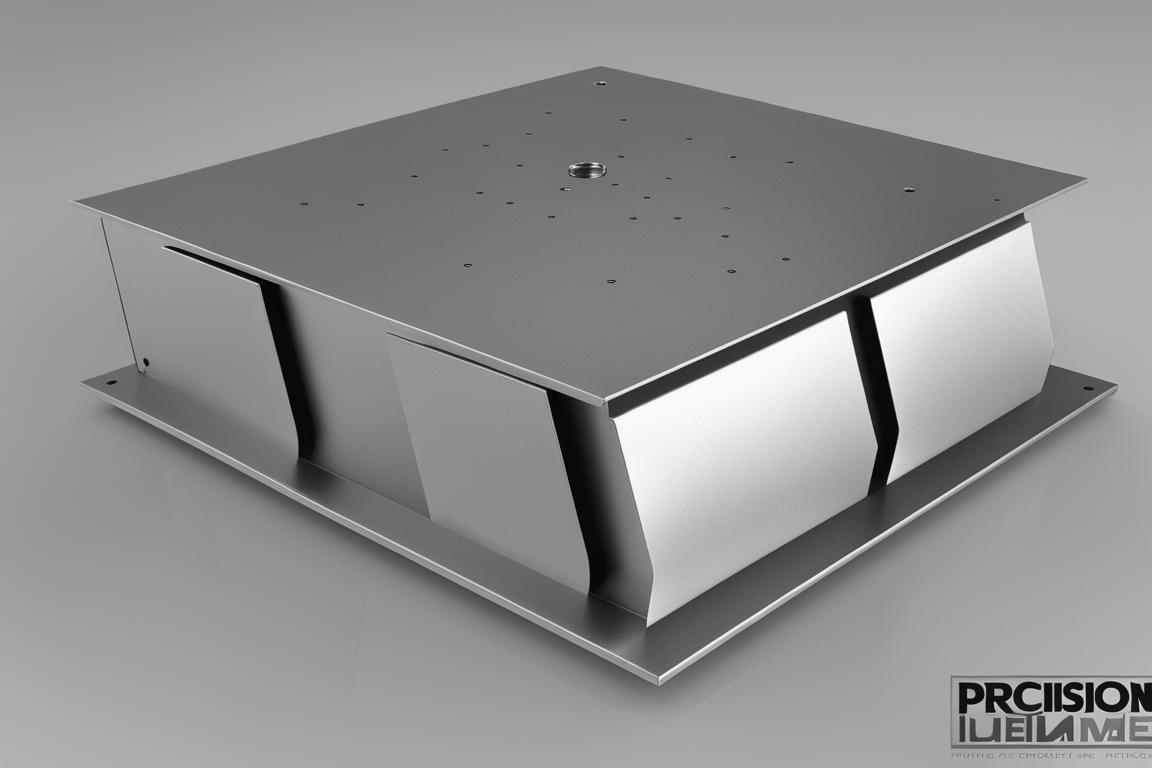

Are you curious about the role of custom sheet metal boxes in today's industries? These specialized containers have become increasingly popular due to their adaptability and precision. Unlike standard off-the-shelf options, custom sheet metal boxes are designed to meet specific needs, making them ideal for sectors like electronics, aerospace, and automotive. Whether it’s for storage, transport, or protection, these boxes offer tailored solutions that fit perfectly into unique applications.

Advantages of Custom Sheet Metal Boxes

Custom sheet metal boxes come with numerous advantages that make them a preferred choice over mass-produced alternatives. One of the main benefits is precision. These boxes are made to exact specifications, ensuring they fit perfectly into your setup. They also offer durability, as sheet metal is known for its strength and resistance to wear and tear. Plus, there's the customization aspect—whether it's color, finish, or branding, you can tailor the box to match your style or company identity.

The Design and Engineering Process

Creating a custom sheet metal box involves a detailed design and engineering process. It starts with CAD (Computer-Aided Design), where engineers create precise 3D models that guide the entire production. This stage helps identify potential issues early on and ensures the final product meets all requirements. After the design is approved, a prototype is often built to test functionality before moving to full-scale manufacturing.

CAD Design in Custom Sheet Metal Boxes

CAD software allows designers to visualize the final product in detail, ensuring every measurement and feature is accurate. This not only improves efficiency but also reduces the chances of errors during production. By using CAD, manufacturers can save time and resources while delivering high-quality results.

Choosing the Right Materials

The materials used in custom sheet metal boxes play a big role in their performance. Common options include aluminum, stainless steel, and carbon steel. Each has its own strengths: aluminum is lightweight and corrosion-resistant, making it perfect for outdoor use; stainless steel is durable and easy to clean, ideal for medical or food-related applications; and carbon steel offers high strength, suitable for heavy-duty environments.

| Fabrication Technique | Description |

|---|---|

| Cutting | Shaping metal sheets using laser cutting or shearing methods based on design specs. |

| Bending | Forming the structural parts of the box through bending techniques. |

| Welding | Joining components together using TIG or MIG welding for strong, seamless connections. |

| Finishing | Enhancing appearance and durability with treatments like powder coating or anodizing. |

Fabrication Techniques Explained

Fabricating custom sheet metal boxes requires several key steps. First, the metal is cut to size using advanced tools like lasers or shears. Then, the pieces are bent into shape using hydraulic presses or brake presses. Once the structure is formed, welding is used to join the parts together. Finally, finishing processes such as painting or polishing give the box a professional look and improve its longevity.

Welding Techniques in Sheet Metal Fabrication

Welding is a critical step in creating strong and durable sheet metal boxes. TIG welding is often used for thin metals, providing clean and precise joints. MIG welding, on the other hand, is faster and more efficient for thicker materials. Both methods ensure the box remains sturdy and secure over time.

Ensuring Quality and Accuracy

Maintaining precision and quality control throughout the manufacturing process is essential. Every step—from design to final assembly—is carefully monitored to ensure the product meets the highest standards. Regular inspections and testing help catch any issues early, guaranteeing that the final product is both functional and reliable.

Customization Options Available

One of the biggest advantages of custom sheet metal boxes is the wide range of customization options. You can choose from various shapes, sizes, colors, and finishes to suit your needs. Adding logos, labels, or even internal compartments makes each box unique and functional for specific purposes. This flexibility makes custom sheet metal boxes a top choice for businesses looking for personalized solutions.

Real-World Applications of Custom Sheet Metal Boxes

Custom sheet metal boxes are used across many industries. In the electronics sector, they protect sensitive components during transport and storage. In medical equipment, they ensure hygiene and safety when handling critical devices. In the automotive industry, they provide organized and secure storage for parts and tools. These examples show how versatile and essential custom sheet metal boxes are in modern manufacturing.

Trends Shaping the Future of Sheet Metal Box Fabrication

The sheet metal box industry is evolving rapidly. With the rise of digital design tools, projects can be completed faster and with greater accuracy. Sustainable practices are also becoming more common, with companies focusing on reducing waste and reusing materials. Automation in manufacturing is improving efficiency and quality, making it easier to produce complex designs at scale.

How to Choose the Right Fabrication Partner

Selecting the right manufacturer is crucial for getting the best results. Look for a partner with proven experience in sheet metal fabrication and a strong track record of delivering high-quality products. A good supplier should also be able to handle complex designs and provide excellent customer support. Choosing the right company ensures your custom sheet metal box is made to perfection.

Maintaining Your Custom Sheet Metal Boxes

To keep your custom sheet metal boxes in top condition, regular maintenance is important. Clean them regularly to prevent rust and dirt buildup. Avoid exposing them to harsh chemicals or extreme temperatures. If they have moving parts like hinges or latches, lubricate them periodically to ensure smooth operation. Following these simple tips will extend the life of your boxes and keep them looking great for years.

What’s Next for Custom Sheet Metal Boxes?

The future of custom sheet metal boxes looks promising. Innovations like 3D printing and smart integration are opening up new possibilities. Companies are also exploring eco-friendly materials and energy-efficient processes to reduce environmental impact. As technology advances, we can expect even more creative and sustainable solutions in the world of sheet metal fabrication.

Frequently Asked Questions

Who can benefit from custom sheet metal boxes?

Businesses in need of precise and durable storage solutions, especially those requiring tailored dimensions and features.

What makes custom sheet metal boxes unique?

They are specifically designed to fit individual needs, offering unmatched customization and precision.

How are custom sheet metal boxes fabricated?

They are created using advanced sheet metal fabrication techniques, including cutting, bending, welding, and finishing.

Who can I contact for custom sheet metal box orders?

You can reach out to experienced sheet metal fabrication companies that specialize in custom solutions.

What if I need a custom sheet metal box quickly?

Many manufacturers offer expedited services to meet urgent deadlines without compromising quality.

How durable are custom sheet metal boxes?

Custom sheet metal boxes are incredibly sturdy and long-lasting, designed to withstand tough conditions.

{"@context":"https://schema.org","@type":"FAQPage","mainEntity":[{"@type": "Question", "name": "Who can benefit from custom sheet metal boxes?", "acceptedAnswer": {"@type": "Answer", "text": "Businesses in need of precise and durable storage solutions."}}, {"@type": "Question", "name": "What makes custom sheet metal boxes unique?", "acceptedAnswer": {"@type": "Answer", "text": "They are tailored to specific dimensions and designs."}}, {"@type": "Question", "name": "How are custom sheet metal boxes fabricated?", "acceptedAnswer": {"@type": "Answer", "text": "They are crafted using precision sheet metal fabrication techniques."}}, {"@type": "Question", "name": "Who can I contact for custom sheet metal box orders?", "acceptedAnswer": {"@type": "Answer", "text": "You can reach out to experienced sheet metal fabrication companies."}}, {"@type": "Question", "name": "What if I need a custom sheet metal box quickly?", "acceptedAnswer": {"@type": "Answer", "text": "Some fabrication companies offer expedited services for urgent orders."}}, {"@type": "Question", "name": "How durable are custom sheet metal boxes?", "acceptedAnswer": {"@type": "Answer", "text": "Custom sheet metal boxes are incredibly sturdy and long-lasting."}}]}Customized Seamless Steel Tube

Shandong Yuzhong Steel Co.,Ltd. , https://www.cnyzsteel.com