Discover the World of Custom Sheet Metal Boxes

- Why custom sheet metal boxes are essential across different industries.

- What you need to know about their benefits, design, materials, and customization options.

- How to select a reliable manufacturer and ensure long-term performance.

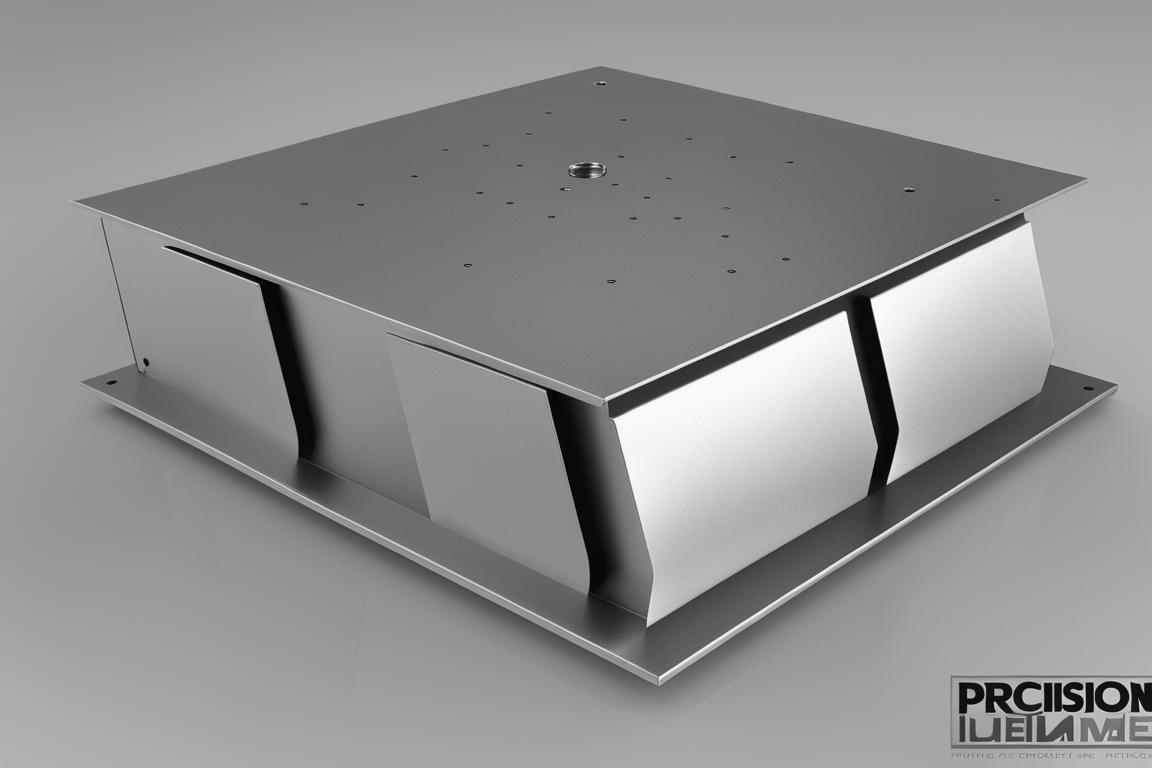

Are you curious about how custom sheet metal boxes can transform your storage or transport needs? In today’s fast-paced industrial world, these boxes have become increasingly popular due to their flexibility, strength, and ability to meet specific requirements. Unlike standard products, custom sheet metal boxes are designed from scratch to fit unique dimensions, functions, and aesthetics. They play a vital role in sectors like electronics, aerospace, automotive, and more, where precision and durability are non-negotiable.

Advantages of Custom Sheet Metal Boxes

Custom sheet metal boxes offer a range of advantages that make them a preferred choice over generic alternatives. One of the biggest benefits is precision engineering. By tailoring the box to exact measurements, you maximize space usage and ensure a perfect fit for your application. The durability of sheet metal also means the box can withstand harsh conditions, protecting sensitive equipment or components. Additionally, the customizable finish allows for branding, color choices, and surface treatments that enhance both function and appearance.

Design and Engineering Process

Creating a custom sheet metal box involves a detailed process that starts with CAD (Computer-Aided Design). This digital tool helps engineers visualize the final product, ensuring accuracy and efficiency. Prototyping is then used to test the design before mass production begins. This iterative approach ensures that every detail is refined, making the final product not only functional but also cost-effective.

CAD Design in Custom Sheet Metal Boxes

CAD software allows designers to create 3D models that accurately represent the box’s structure. This makes it easier to identify potential issues early on and make necessary adjustments. It also speeds up the manufacturing process by providing clear instructions to the fabrication team.

Choosing the Right Materials

The material selection is a crucial step in the fabrication of custom sheet metal boxes. Common options include aluminum, stainless steel, and carbon steel, each offering distinct benefits. Aluminum is lightweight and resistant to corrosion, making it ideal for applications requiring portability. Stainless steel is strong and aesthetically pleasing, often used in high-end environments. Carbon steel, while heavier, provides excellent structural integrity for heavy-duty uses.

| Fabrication Technique | Description |

|---|---|

| Cutting | Shaping metal sheets using laser cutting or shearing for precise dimensions. |

| Bending | Using press brakes to form the metal into the desired shape. |

| Welding | Joining parts with TIG or MIG welding for strong, seamless connections. |

| Finishing | Applying coatings like powder coating or anodizing for protection and style. |

Fabrication Techniques Explained

Fabricating a custom sheet metal box involves several key steps. First, the metal is cut according to the design specifications. Then, it is bent into the correct shape using specialized machinery. After that, the pieces are welded together to form a sturdy structure. Finally, finishing techniques such as painting or polishing are applied to improve the box’s appearance and protect it from wear and tear.

Welding Techniques in Sheet Metal Fabrication

Welding is one of the most important steps in creating a durable custom sheet metal box. TIG welding is known for its precision and clean finish, making it ideal for delicate or visible joints. MIG welding, on the other hand, is faster and better suited for thicker materials, offering strong and reliable connections.

Ensuring Quality and Precision

Maintaining high standards of precision and quality control is essential in producing custom sheet metal boxes. Each stage of the process—from cutting to finishing—is inspected to ensure it meets the required specifications. This attention to detail guarantees that the final product is not only functional but also built to last.

Customization Options Available

One of the greatest strengths of custom sheet metal boxes is the wide range of customization options available. You can choose from various shapes, sizes, and finishes to match your specific needs. Adding features like handles, hinges, or custom logos allows you to create a truly personalized solution that reflects your brand or purpose.

Real-World Applications

Custom sheet metal boxes are used in a variety of real-world scenarios. For example:

- Electronics Industry: Used to house and protect sensitive components during transport and storage.

- Medical Equipment: Designed to store and transport medical devices safely and hygienically.

- Automotive Sector: Helps organize and protect car parts, improving efficiency in workshops and warehouses.

Trends Shaping the Industry

The sheet metal fabrication industry is constantly evolving. With the rise of digital tools, design processes have become faster and more accurate. Sustainability is also becoming a priority, with many companies adopting eco-friendly practices like recycling and energy-efficient manufacturing. Meanwhile, automation is improving productivity and reducing human error, allowing for higher-quality outputs at lower costs.

How to Choose the Right Manufacturer

Selecting the right fabrication partner is crucial. Look for a company with experience in custom sheet metal work, a proven track record, and the ability to handle complex designs. Reading customer reviews and checking references can also help you find a reliable partner who delivers quality results on time and within budget.

Tips for Maintaining Your Sheet Metal Box

To keep your custom sheet metal box in top condition, regular maintenance is key. Clean it regularly to prevent rust or dirt buildup. Avoid exposing it to extreme temperatures or corrosive chemicals. Lubricate moving parts like hinges and latches to ensure smooth operation. Following these simple steps will extend the life of your box and maintain its performance.

Future of Custom Sheet Metal Fabrication

The future of custom sheet metal boxes looks bright, with new technologies like 3D printing and smart integration opening up new possibilities. As sustainability becomes more important, we can expect to see more eco-friendly materials and energy-efficient processes. These innovations will continue to shape the industry and offer even more value to customers.

Frequently Asked Questions

Who can benefit from custom sheet metal boxes?

Businesses looking for tailored, durable, and efficient storage solutions.

What makes custom sheet metal boxes special?

They are made to fit specific needs, offering unmatched precision and adaptability.

How are they made?

Through advanced fabrication methods like cutting, bending, welding, and finishing.

Where can I get one?

By contacting experienced sheet metal fabrication companies.

Can I get it quickly?

Some manufacturers offer expedited services for urgent orders.

Are they strong and long-lasting?

Yes, custom sheet metal boxes are known for their durability and reliability.

{"@context":"https://schema.org","@type":"FAQPage","mainEntity":[{"@type": "Question", "name": "Who can benefit from custom sheet metal boxes?", "acceptedAnswer": {"@type": "Answer", "text": "Businesses looking for tailored, durable, and efficient storage solutions."}}, {"@type": "Question", "name": "What makes custom sheet metal boxes special?", "acceptedAnswer": {"@type": "Answer", "text": "They are made to fit specific needs, offering unmatched precision and adaptability."}}, {"@type": "Question", "name": "How are they made?", "acceptedAnswer": {"@type": "Answer", "text": "Through advanced fabrication methods like cutting, bending, welding, and finishing."}}, {"@type": "Question", "name": "Where can I get one?", "acceptedAnswer": {"@type": "Answer", "text": "By contacting experienced sheet metal fabrication companies."}}, {"@type": "Question", "name": "Can I get it quickly?", "acceptedAnswer": {"@type": "Answer", "text": "Some manufacturers offer expedited services for urgent orders."}}, {"@type": "Question", "name": "Are they strong and long-lasting?", "acceptedAnswer": {"@type": "Answer", "text": "Yes, custom sheet metal boxes are known for their durability and reliability."}}]NM Steel Plate,NM500 Steel Sheet,NM400 Steel Plate,NM Steel Sheet NM450 ,High Strength Wear Plate

Shandong Yuzhong Steel Co.,Ltd. , https://www.cnyzsteel.com